Lighting principle

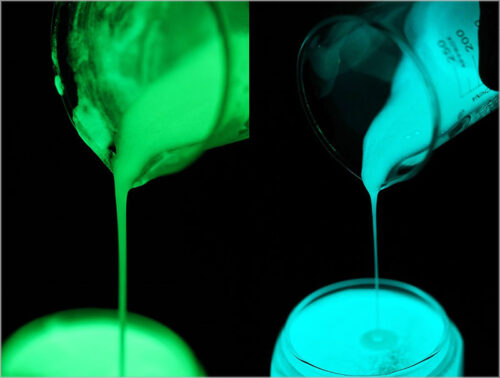

Glow in the dark paint is a mixture of glow in the dark powder and transparent paint. The self-luminous principle is that the material absorbs sunlight, lamp light, or other visible light and storage them, then emit the brightness in the dark environment without any electricity power. When the light is completely released,the material starts to be charged again when surroundings lighted up. It can go on an infinite loop.

Application

It can be widely used in indoor and outdoor walls and ground, such as escape signs, safety signs, road markings, advertising signs, industrial metal, and wood surfaces, also for low-level emergency lighting.

Our advantage

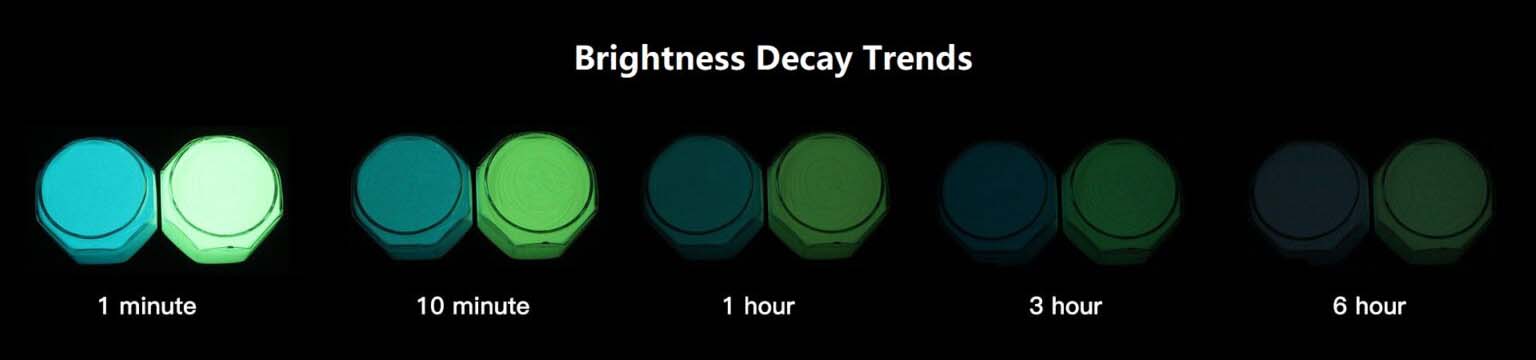

The quality of glow in the dark paint is decided by the powder’s brightness and its dosage. Our glow in the dark paint uses ultra-bright powder and with high dosage. The main emulsion is water-based acrylic. It is non-toxic, eco-friendly without VOC and with long afterglow.

APPLICATION SURFACE

This glow in the dark acrylic water-based paint is suitable for 4 kinds of surfaces, floor, wall, metal and wood.

Wall Surface

Road Surface

Metal Surface

Wood Surface

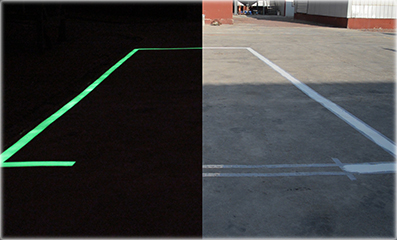

MAKE GLOW PARKING LINES

The specific operation method of drawing parking lines with glow in the dark paint.

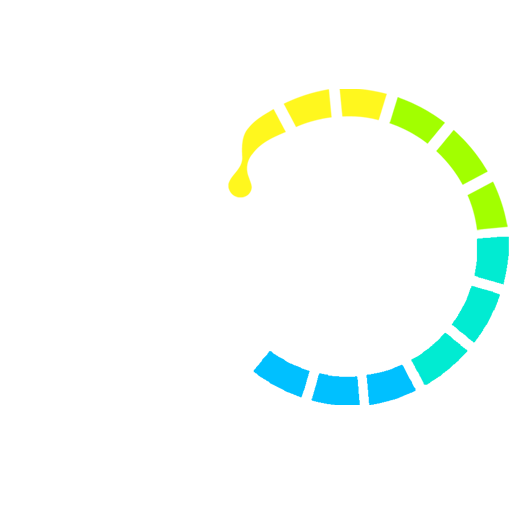

GLOW IN THE DARK PAINT COLOR

DISPLAY OF PACKAGING